Industry information

Company News

- Imitation stone patterned aluminum veneer: a rising star in the construction industry as a "stone substitute"

- Imitation wood grain aluminum veneer: a fashionable "disguise" for modern architecture

- The unique charm of stone patterned aluminum veneer reveals the new trend of home decor

- Aluminum veneer is the new trend, creating a new fashion in modern architecture!

- Aluminum veneer: the "fashionable coat" of modern architecture

Industry dynamics

- Imitation stone patterned aluminum veneer: the new darling of fashionable building materials

- Imitation wood grain aluminum veneer, the new favorite of modern architecture?

- How to choose the thickness of hyperbolic aluminum veneer?

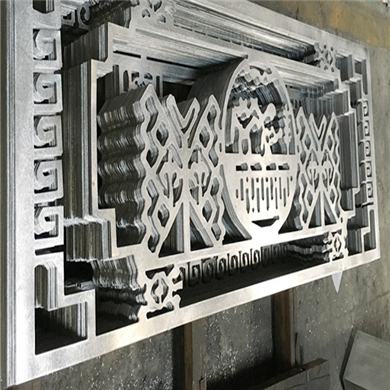

- Aluminum veneer customization, creating a unique spatial aesthetic

- Advantages and characteristics of perforated fluorocarbon aluminum veneer

Frequently asked questions

- Can aluminum veneer be used for architectural arch design?

- What is the strength of aluminum veneer?

- What impact does the weight of aluminum veneer have on building structures?

- Can aluminum veneer be applied to different styles of architectural exterior design?

- What is the anti mold performance of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786@qq.com

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

How to improve the corrosion resistance of aluminum veneer?

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: 2022-02-26 04:37:53

- Click:0

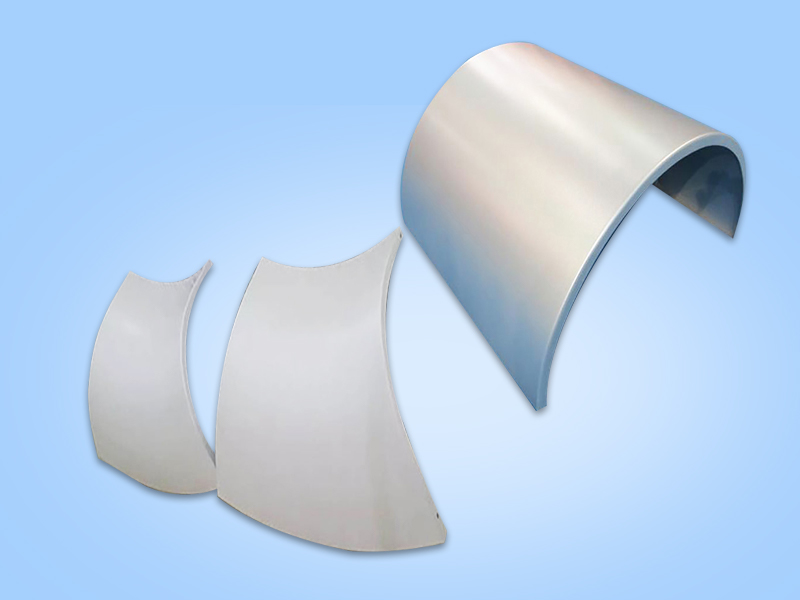

Aluminum veneerIt is a material widely used in fields such as construction and decoration, and its advantages of lightweight, high strength, and corrosion resistance make it an ideal choice. Aluminum veneer may also encounter some corrosion problems during use, which can affect its service life and appearance. Improving the corrosion resistance of aluminum veneer is very important. Below, we will provide a detailed introduction on how to improve the corrosion resistance of aluminum veneer.

1. Surface treatment

Surface treatment is one of the important means to improve the corrosion resistance of aluminum veneer. Common surface treatment methods include spraying, anodizing, electrophoretic coating, etc. These methods can increase the hardness and wear resistance of the surface of aluminum veneer, thereby reducing corrosion on the surface of aluminum veneer. Anodizing is a commonly used surface treatment method that can form an oxide film on the surface of aluminum veneer, which has excellent corrosion resistance.

1. Choose the appropriate aluminum alloy material

Different types of aluminum alloy materials have different corrosion resistance properties. When selecting aluminum veneer, it is necessary to choose the appropriate aluminum alloy material based on the specific usage environment and requirements. For example, for buildings in marine environments, 3 series or 5 series aluminum alloy materials with good corrosion resistance can be selected; For buildings in interior decoration, 6 series or 7 series aluminum alloy materials with good decorative effects can be selected.

1. Strengthen maintenance and upkeep

In addition to surface treatment and selecting suitable aluminum alloy materials, strengthening the maintenance of aluminum veneer is also an important means to improve its corrosion resistance. For example, regularly cleaning the dirt and dust on the surface of aluminum veneer can reduce the occurrence of corrosion; Regularly inspect the connections of aluminum veneer for looseness and corrosion, and promptly repair and replace them.

Improving the corrosion resistance of aluminum veneer requires multiple approaches. By surface treatment, selecting suitable aluminum alloy materials, and strengthening maintenance, the corrosion resistance of aluminum veneer can be effectively improved, and its service life and lifespan can be extended. Attention should also be paid to the details in practical applications, such as installation methods, usage environments, etc., to ensure that aluminum veneer can meet actual needs and achieve the expected results.

Customer service QQ

Customer service QQ