Industry information

Company News

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum veneer customization, creating a new trend of personalized space

- Imitation stone patterned aluminum veneer: the beauty of nature, the choice of modernity

- Stone patterned aluminum veneer: a unique artistic choice for modern architecture

- Customized aluminum veneer to make buildings more in line with people's cultural connotations

Industry dynamics

- Aluminum veneer customization, creating a new trend of personalized space

- What is aluminum veneer?

- Technologically advanced fluorocarbon aluminum veneer

- Stone patterned aluminum veneer: natural charm in modern architecture

- Why choose aluminum veneer instead of other building materials?

Frequently asked questions

- Can aluminum veneer be applied to different styles of architectural exterior design?

- What is the strength of aluminum veneer?

- Can aluminum veneer be used for architectural arch design?

- Is the fire resistance of aluminum veneer related to its material?

- What are the color and style options for aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786@qq.com

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

What is aluminum veneer?

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: 2022-03-07 22:57:51

- Click:0

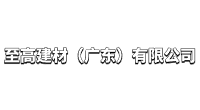

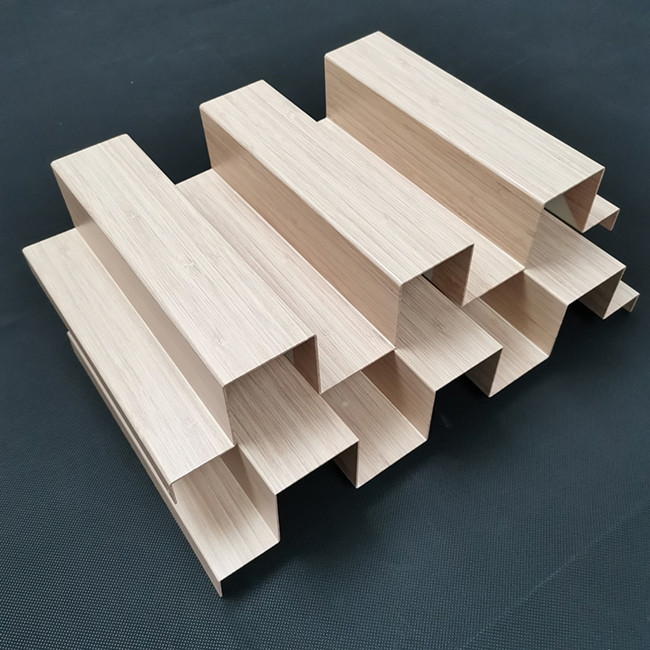

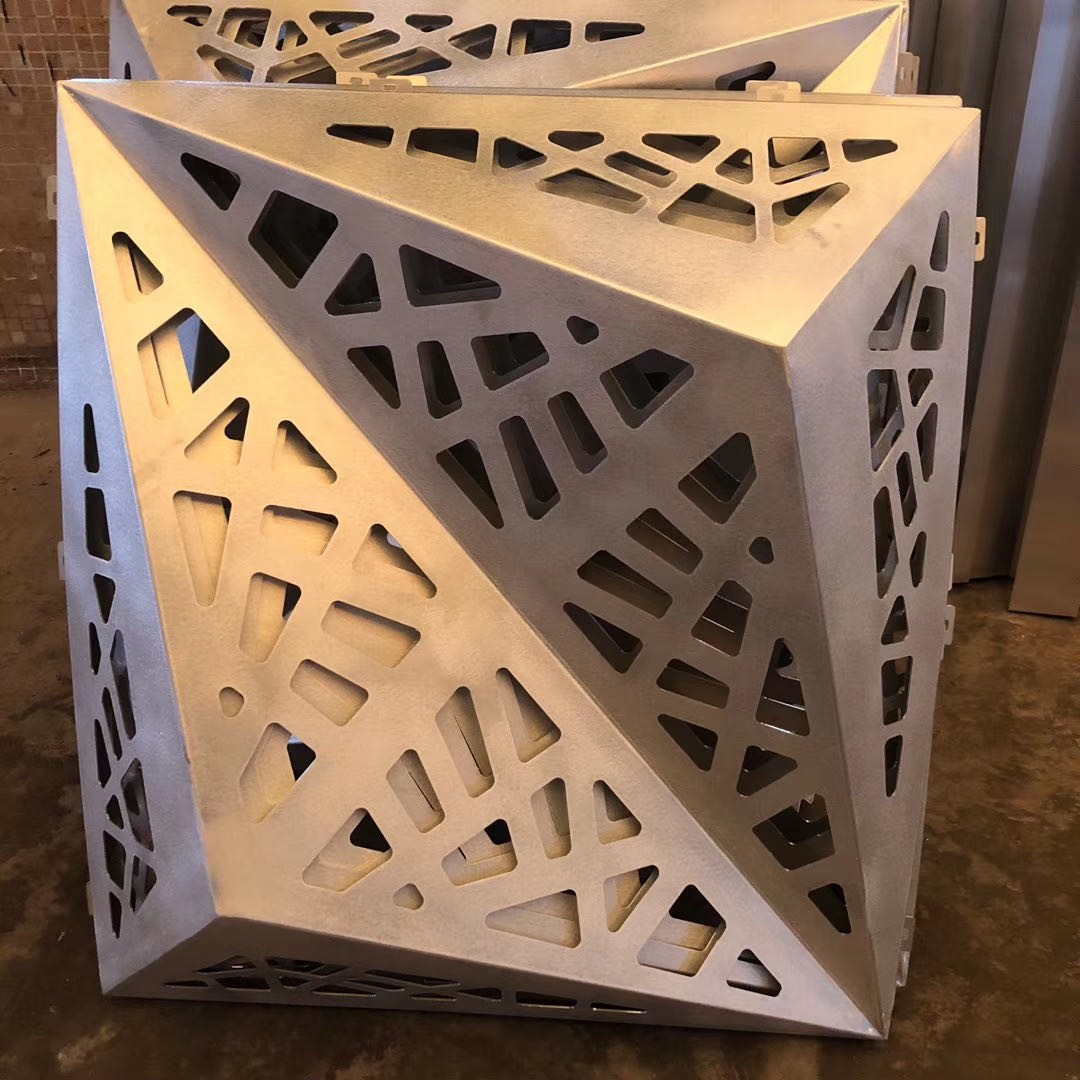

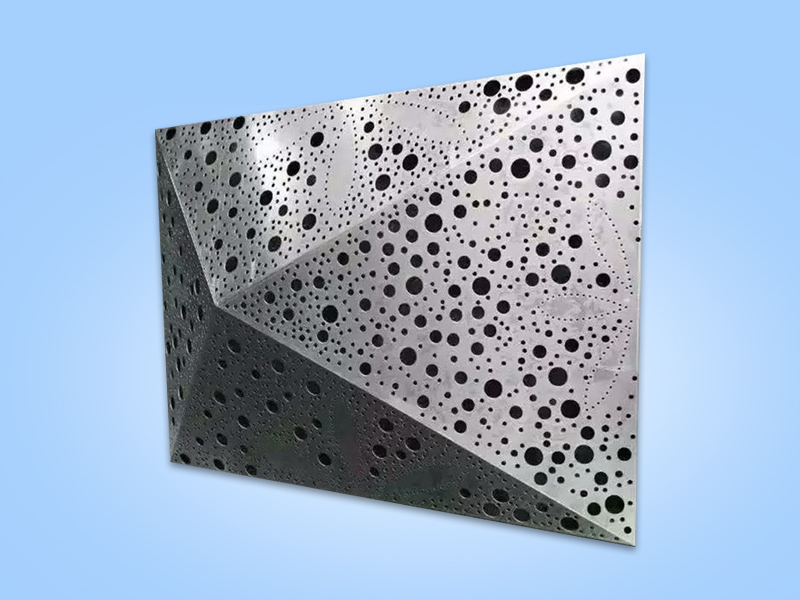

Aluminum veneerIt is a building material made of aluminum alloy sheet through special processing. It has the advantages of lightweight, high strength, corrosion resistance, and easy processing, and is widely used in fields such as building decoration and industrial equipment manufacturing.

The production process of aluminum veneer generally consists of the following steps:

1. Raw material preparation: The main raw materials for aluminum veneer are aluminum and surface treatment agents. Aluminum materials are usually made of 1 series or 3 series aluminum alloys, and surface treatment agents include various methods such as anodizing, spraying, electrophoretic coating, etc.

2. Cutting and processing: Cut the aluminum material into the required size sheet according to the design requirements.

3. Surface treatment: Surface treatment of aluminum materials to give them the desired color, glossiness, hardness, and other properties. Common surface treatment methods include anodizing, spraying, electrophoretic coating, etc.

4. Forming processing: The processed aluminum material is formed into the desired shape of an aluminum veneer.

5. Follow up processing: Perform subsequent processing on the produced aluminum veneer, such as punching, bending, slotting, etc., to meet specific usage requirements.

Aluminum veneer has the following advantages:

1. Lightweight: Aluminum veneer is lightweight, easy to handle and install, and also reduces the weight of the building.

2. High strength: Aluminum veneer has high strength and stiffness, and can withstand large loads and wind pressures.

3. Corrosion resistance: After anodizing or spraying treatment on the surface of aluminum veneer, it has strong corrosion resistance and is not easily oxidized or corroded.

4. Easy to process: Aluminum veneer is easy to process and shape, and can be designed and manufactured in various shapes according to needs.

Aluminum veneer, as a new type of building material, has the advantages of lightweight, high strength, and corrosion resistance, and is widely used in fields such as building decoration and industrial equipment manufacturing. With the continuous advancement and development of technology, it is believed that aluminum veneer will have even broader development space in future application fields.

Customer service QQ

Customer service QQ