Industry information

Company News

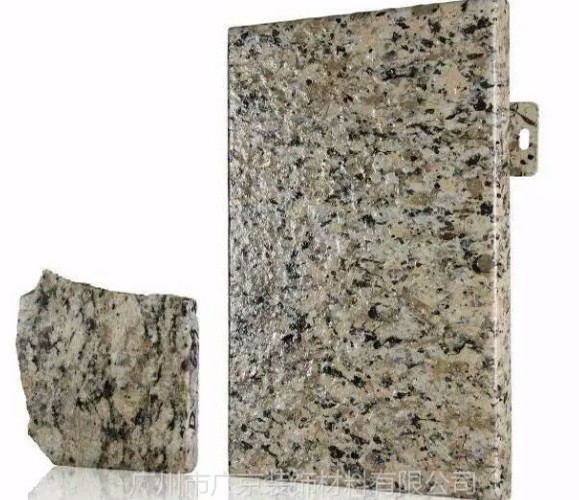

- Imitation stone patterned aluminum veneer: the "natural" choice for modern architecture

- Imitation wood grain aluminum veneer: the retro style of modern architecture

- Imitation wood grain aluminum veneer, the retro style code of modern architecture

- Imitation stone patterned aluminum veneer: the beauty of nature, the choice of modernity

- Imitation wood grain aluminum veneer: a perfect fusion of modernity and nature

Industry dynamics

- Imitation wood grain aluminum veneer: the green new favorite of modern architecture

- Imitation stone patterned aluminum veneer: the fashionable new darling of modern architecture

- Aluminum veneer makes buildings more environmentally friendly and sustainable

- Aluminum veneer: not just sheet metal, but also a new favorite of architectural aesthetics

- The unique charm of wood grain aluminum veneer creates a new trend in home decor

Frequently asked questions

- What impact does the weight of aluminum veneer have on building structures?

- What is the discoloration performance of aluminum veneer?

- Can the insulation function of aluminum veneer reduce the amount of cement used in buildings?

- Is the fire resistance of aluminum veneer related to its material?

- Can aluminum veneer be used for architectural arch design?

contact us

Mobile:+86 15627778610

Email: 2201229786@qq.com

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Characteristics and Applications of Aluminum Single Panel Coated with Styling Rollers

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: 2022-03-03 10:16:32

- Click:0

Shape roller coatingAluminum veneerIt is a very unique decorative method that can use roller coating technology to treat the surface of aluminum veneer, presenting different textures, colors, and textures, thus achieving a beautiful effect. When designing the shape of aluminum veneer, roller coating aluminum veneer is a very important consideration because it can make the entire decorative effect more colorful, and also improve the durability and waterproof performance of aluminum veneer. This article will provide a detailed introduction to the advantages and features of this new type of decoration method, focusing on the characteristics and applications of aluminum veneer coated with shape rollers.

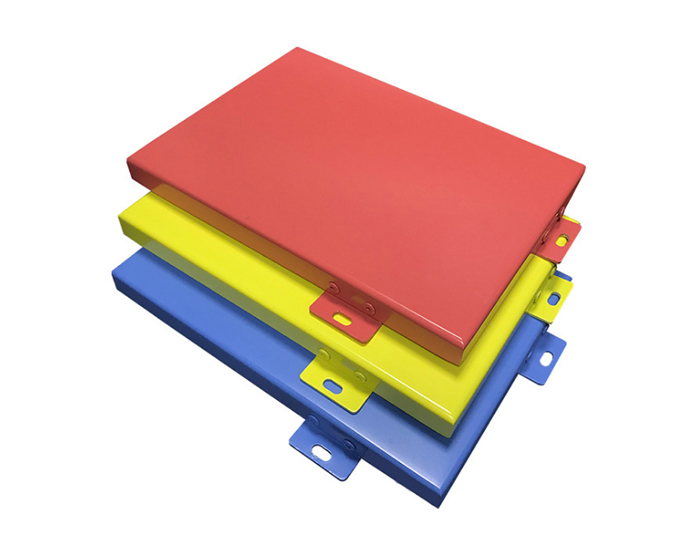

The shape roller coated aluminum veneer has a very rich texture and color. By using different roller coating techniques and pigments, various textures and colors can be produced, such as wood grain, stone grain, metallic texture, etc., to meet the different needs and preferences of customers. The shape roller coated aluminum veneer can also be customized according to customer requirements to create a unique, beautiful and elegant architectural appearance.

Roll coated aluminum veneer has very high decorative performance. Due to its special surface treatment, it has better wear resistance, corrosion resistance, and waterproof performance, making it suitable for various environments and occasions. For example, in commercial buildings, aluminum veneer coated with shape rollers can be used to decorate walls, ceilings, doors and windows, creating a fashionable and modern atmosphere; In residential areas, aluminum veneer coated with shape rollers can be used to create a warm and comfortable atmosphere.

The shape roller coated aluminum veneer also has a very simple installation method. Due to its specially treated surface, it can be directly pasted or installed on walls or ceilings without the need for complex processing and treatment. This simple installation method can not only improve construction efficiency, but also reduce construction costs.

Roll coating aluminum veneer is a very unique decorative method, which can treat the surface of aluminum veneer through roll coating technology to present different textures, colors, and textures, thereby achieving a beautiful effect. With the development of technology and changes in people's aesthetic concepts, it is believed that there will be broader development space for the application of shape roller coated aluminum veneer in the future.

Customer service QQ

Customer service QQ