Industry information

Company News

- Imitation stone patterned aluminum veneer: a natural interpretation of architectural aesthetics

- Wood grain aluminum veneer, the new darling of modern architecture

- Imitation wood grain aluminum veneer: the "green" choice for modern architecture

- Aluminum veneer: the new darling of architectural aesthetics

- hello everyone! Today let's talk about imitation stone patterned aluminum veneer. I didn't know what it meant before

Industry dynamics

- Imitation wood grain aluminum veneer: the new favorite of aluminum materials, the beauty of nature

- Aluminum veneer customization, creating a new trend of personalized space

- Stone patterned aluminum veneer, a perfect combination of natural beauty and modern craftsmanship

- Aluminum veneer customization, creating a new trend of personalized space

- Advantages and characteristics of perforated fluorocarbon aluminum veneer

Frequently asked questions

- What is the anti mold performance of aluminum veneer?

- Is the fire resistance of aluminum veneer related to its material?

- What impact does the weight of aluminum veneer have on building structures?

- Can aluminum veneer be used for architectural arch design?

- Will the use of aluminum veneer affect the waterproof performance of buildings?

contact us

Mobile:+86 15627778610

Email: 2201229786@qq.com

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

How to test the ventilation performance of perforated aluminum veneer?

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: February 23, 2025 06:47:38

- Click:0

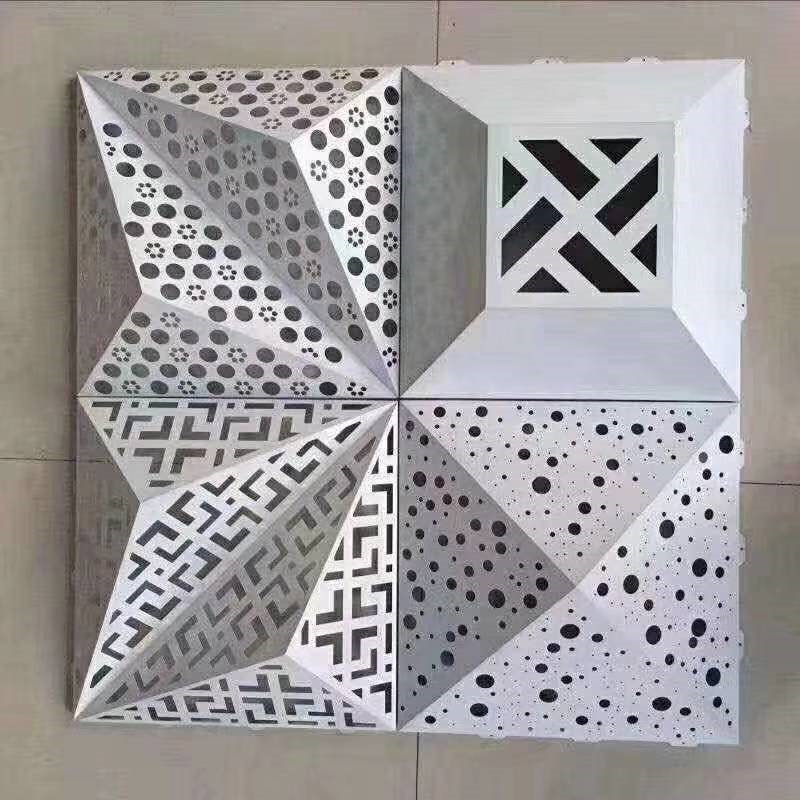

punchingAluminum veneerAs a material widely used in fields such as architectural decoration, billboards, curtain walls, etc., its ventilation performance is also an important aspect. In order to ensure that the ventilation performance of punched aluminum veneer meets the requirements, it is necessary to test and inspect it. The following will introduce how to test the ventilation performance of punched aluminum veneer from the following aspects.

1. Aerodynamic analysis

Firstly, the aerodynamic performance of punched aluminum veneer can be analyzed, including parameters such as wind resistance coefficient and pressure distribution. These parameters can be obtained through numerical calculations or experimental measurements. Through aerodynamic analysis, the resistance of perforated aluminum veneer at different wind speeds can be evaluated to determine whether its ventilation performance meets the requirements.

1. Thermal comfort test

Secondly, the thermal comfort of punched aluminum veneer can be tested to determine whether it can effectively dissipate heat and ventilate. This type of test is generally conducted using a heat transfer test chamber, which simulates different environmental temperature and humidity conditions to test the heat dissipation efficiency and ventilation effect of punched aluminum veneer. Through thermal comfort testing, the ventilation performance of perforated aluminum veneer can be evaluated in different environments.

1. Air quality testing

In addition, the ambient air quality of perforated aluminum veneer can be tested to determine whether it will affect indoor air quality. This type of test is generally conducted using a gas analyzer, which can detect the concentration of harmful substances in the air, such as formaldehyde, benzene, etc. Through air quality testing, the impact of perforated aluminum veneer on indoor air quality can be evaluated, thereby determining whether its ventilation performance meets the requirements.

How to improve the ventilation performance of punched aluminum veneer

To improve the ventilation performance of punched aluminum veneer, the following measures can be taken:

(1) Optimizing structural design: By optimizing the structural design of perforated aluminum veneer, its transparency and ventilation characteristics can be increased, thereby improving its ventilation performance. For example, measures such as inclined angle design and adding drainage channels can reduce the possibility of dust accumulation, thereby further improving ventilation performance.

(2) Strengthening surface treatment process: By enhancing the surface treatment process, the corrosion resistance and wear resistance of punched aluminum veneer can be improved, thereby enhancing its ventilation performance. For example, processes such as anodizing, electrophoretic coating, and fluorocarbon spraying can form a dense and uniform oxide film or coating, thereby improving its transparency and breathability.

(3) Strengthening post-processing: By enhancing post-processing processes such as grinding and polishing, surface scratches and uneven areas can be removed, making the surface of punched aluminum veneer smoother and increasing its transparency and breathability.

By using methods such as aerodynamic analysis, thermal comfort testing, and air quality inspection, the ventilation performance of perforated aluminum veneer can be effectively tested and verified to meet the needs of different occasions. By strengthening the management of raw material quality, optimizing surface treatment processes, and enhancing structural design management, the ventilation performance of punched aluminum veneer can be further improved.

Customer service QQ

Customer service QQ