Industry information

Company News

- The unique charm of stone patterned aluminum veneer: a visual and material encounter

- Aluminum veneer: the 'invisible hero' of modern architecture

- Stone patterned aluminum veneer: a work of art in the aluminum industry

- Aluminum veneer customization, creating a new trend of personalized space

- Friends! Today, let's talk about a material that is becoming increasingly popular in the construction industry - imitation stone

Industry dynamics

- Imitation stone patterned aluminum veneer: delicate interpretation of architectural art

- Application analysis of 2.0mm perforated aluminum veneer in architectural decoration

- Imitation wood grain aluminum veneer: a green choice for modern architecture

- Material selection and characteristic analysis of aluminum veneer for column ceiling

- Stone patterned aluminum veneer: the new darling of architectural aesthetics

Frequently asked questions

- Is the fire resistance of aluminum veneer related to its material?

- What are the color and style options for aluminum veneer?

- What impact does the weight of aluminum veneer have on building structures?

- Can aluminum veneer be applied to different styles of architectural exterior design?

- What is the strength of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786@qq.com

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Process characteristics and advantages of carved curved aluminum veneer

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: February 28, 2025 23:53:41

- Click:0

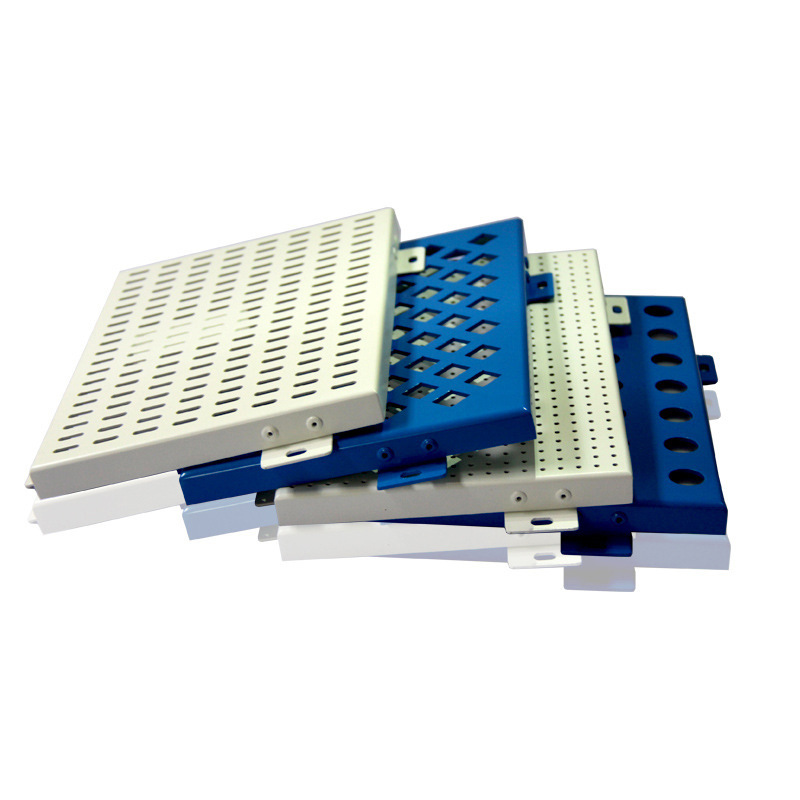

Carved arc shapeAluminum veneerIt is a very popular building material with various advantages such as delicacy, beauty, and durability. It can be widely applied to the exterior walls, ceilings, interior walls, and other parts of buildings, adding more artistic atmosphere and beauty to the architecture. The following will provide a detailed introduction to the process characteristics and advantages of carved curved aluminum veneer.

1、 Process characteristics

The production of carved curved aluminum veneer requires multiple processes, including design, molding, cutting, polishing, and coating. Design is the core link of the entire production process, which needs to be designed according to the customer's requirements and the actual situation of the building. The mold making stage requires the use of high-quality materials and advanced manufacturing processes to ensure the quality and accuracy of the mold. The cutting stage requires the use of CNC machine tools for precise cutting to ensure the dimensional accuracy and surface quality of the aluminum veneer. During the polishing stage, a grinder is required to finely polish the aluminum veneer to ensure its surface quality and glossiness. During the coating stage, different colors and coatings need to be selected for application to meet the diverse needs of customers.

2、 Advantages

1. Exquisite appearance: The carved curved aluminum veneer has a very unique appearance effect, which can add more artistic atmosphere and beauty to the building. It can present various colors and patterns, such as imitation stone, imitation wood grain, etc., making the entire building more natural and warm.

2. Strong durability: The carved curved aluminum veneer is made of high-quality materials and has very strong durability and corrosion resistance. This allows it to remain stable and not easily damaged in various harsh environments. Its surface treatment can also effectively prevent dust and dirt from affecting it.

3. Easy installation: The installation of carved curved aluminum veneer is very convenient and can be completed through simple accessories and fixing methods. Due to its lightweight and high strength, it can also reduce construction difficulty and time costs.

4. Customizable: The carved curved aluminum veneer can be customized according to customer requirements to create a unique architectural art effect. This can not only meet the personalized needs of different customers, but also enhance the artistic value and ornamental value of the building.

The carved curved aluminum veneer has the advantages of exquisite appearance, strong durability, easy installation, and customization. In the future field of architectural decoration, it will continue to play a more important role in creating more beautiful and practical architectural artworks for people.

Customer service QQ

Customer service QQ