Industry information

Company News

- Aluminum veneer customization, creating exclusive space and new fashion

- The unique charm of stone patterned aluminum veneer: savoring the fashionable beauty of modern architecture

- Stone patterned aluminum veneer: the beauty of nature, in architecture

- The unique charm of imitation wood grain aluminum veneer makes your home look brand new!

- Stone patterned aluminum veneer: a work of art in the aluminum industry

Industry dynamics

- Aluminum veneer customization, creating a unique home style and new trend

- Service life and maintenance methods of aluminum veneer

- How much do you know about the artistic imitation wood grain in aluminum veneer?

- Specification selection guide for imitation wood grain aluminum veneer

- How to choose the thickness of hyperbolic aluminum veneer?

Frequently asked questions

- What are the color and style options for aluminum veneer?

- Will the use of aluminum veneer affect the waterproof performance of buildings?

- What is the anti mold performance of aluminum veneer?

- Can the insulation function of aluminum veneer reduce the amount of cement used in buildings?

- Can aluminum veneer be applied to different styles of architectural exterior design?

contact us

Mobile:+86 15627778610

Email: 2201229786@qq.com

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

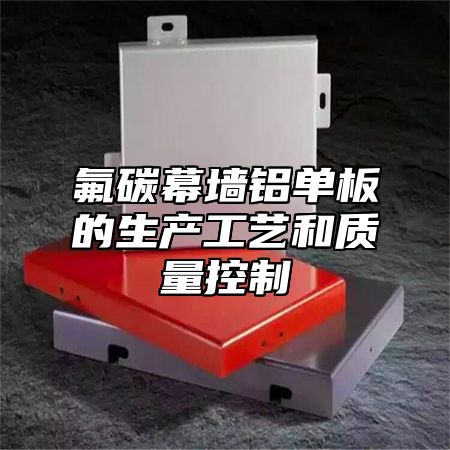

Production process and quality control of fluorocarbon curtain wall aluminum veneer

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: 2022-03-04 04:37:55

- Click:0

Fluorocarbon curtain wallAluminum veneerIt is a modern building material, and its production process and quality control are crucial to ensure the quality and performance of the product. The following will provide a detailed introduction to the production process and quality control of fluorocarbon curtain wall aluminum veneer.

1、 Production process of fluorocarbon curtain wall aluminum veneer

The production process of fluorocarbon curtain wall aluminum veneer mainly includes the following steps:

1. Raw material preparation: Select high-quality aluminum alloy materials as raw materials, undergo strict screening and inspection to ensure the qualification and stability of the materials.

2. Cutting and processing: Cutting and processing raw materials according to design requirements, including processes such as opening, punching, bending, etc., to meet the requirements of different specifications and shapes.

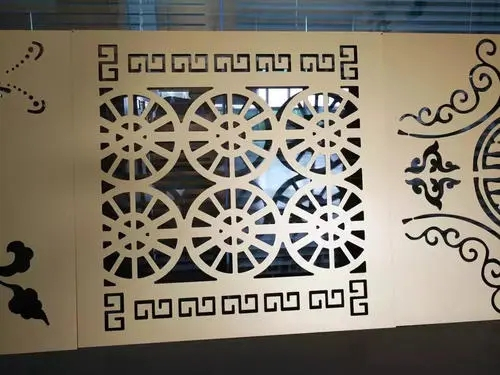

3. Surface treatment: Surface treatment of fluorocarbon curtain wall aluminum veneer after cutting and processing, including anodizing, electrophoretic coating, powder coating and other processes, to improve the corrosion resistance and decorative properties of the product.

4. Assembly and installation: Assemble and install the processed fluorocarbon curtain wall aluminum veneer according to the design requirements, including the installation of connectors, brackets, and other components, to ensure the stability and safety of the product.

2、 Quality control of fluorocarbon curtain wall aluminum veneer

In order to ensure the quality and performance of fluorocarbon curtain wall aluminum veneer, strict quality control is required. The following are the main quality control measures for fluorocarbon curtain wall aluminum veneer:

1. Raw material control: During the production process, strict inspection and screening of raw materials are required to ensure their quality and stability. Regular testing of raw materials is also required to ensure compliance with relevant standards and requirements.

2. Production process control: In the production process, strict control is required according to design requirements and process flow, including cutting accuracy, surface treatment quality, etc., to ensure the quality and performance of the product.

3. Finished product inspection: Before leaving the factory, strict inspection and testing are required, including testing of dimensional accuracy, surface smoothness, strength, etc., to ensure that the product meets relevant standards and requirements.

4. After sales service: After the product is sold, timely after-sales service and technical support need to be provided to solve the problems and difficulties encountered by customers during use.

3、 Summary

As a modern building material, the production process and quality control of fluorocarbon curtain wall aluminum veneer are crucial for ensuring the quality and performance of the product. Through reasonable production processes and strict quality control measures, we can provide the construction industry with higher quality and reliable fluorocarbon curtain wall aluminum veneer products.

Customer service QQ

Customer service QQ