Industry information

Company News

- Imitation stone patterned aluminum veneer: the new darling of architectural aesthetics

- Aluminum veneer customization, creating a new proposition for personalized space!

- Imitation wood grain aluminum veneer: the new favorite of green fashion in modern architecture

- Imitation wood grain aluminum veneer: a perfect fusion of modernity and nature

- Aluminum veneer: a fashionable choice for modern architecture

Industry dynamics

- Color selection and customization of 1.5mm aluminum veneer

- Stone patterned aluminum veneer, harmonious integration of nature and industry

- Stone patterned aluminum veneer: the finishing touch of architectural art

- New trend of aluminum veneer: imitation wood grain, perfect integration of modernity and nature

- 2. The trend of light luxury is coming! Unveiling the Charm of Imitation Stone Pattern Aluminum Veneer 3 New breakthrough in aluminum veneer: imitation

Frequently asked questions

- Can aluminum veneer be used for architectural arch design?

- What is the discoloration performance of aluminum veneer?

- What is the strength of aluminum veneer?

- What impact does the weight of aluminum veneer have on building structures?

- What are the color and style options for aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786@qq.com

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Production process and quality control of engineering baking paint aluminum veneer

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: March 5, 2025 03:49:27

- Click:0

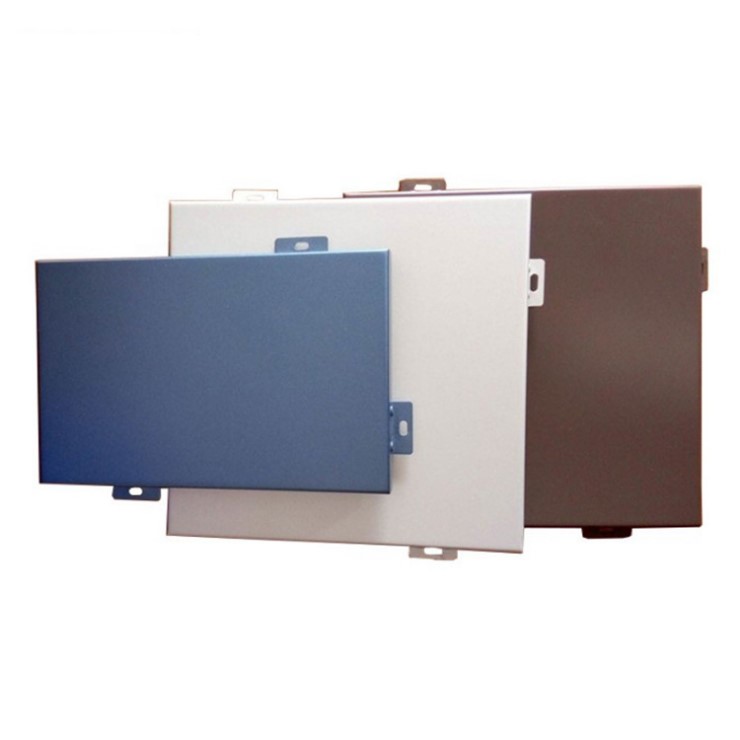

Baking paintAluminum veneerIt is a new type of material widely used in the fields of construction, decoration, etc. Its production process and quality control are crucial to ensure the quality and performance of the product. Below, we will provide a detailed introduction to the production process and quality control of engineering baked aluminum veneer.

1、 Production process

1. Raw material preparation: The main raw material for baked aluminum veneer is aluminum alloy sheet, generally using series such as 1100, 3003, 5052 aluminum alloys. During the production process, strict inspection and screening of raw materials are required to ensure product quality.

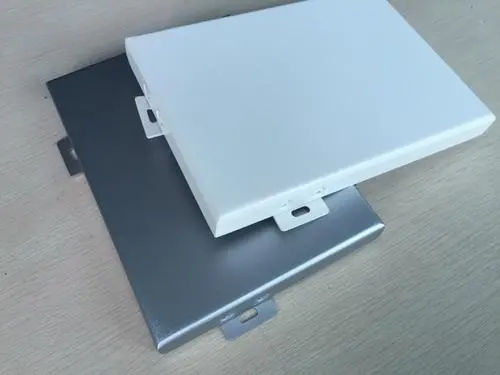

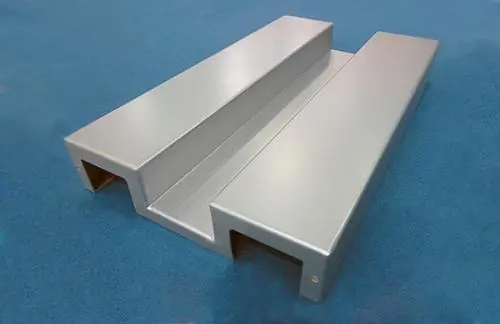

2. Cutting and processing: Cut, bend, punch, and process aluminum alloy sheets according to design requirements to produce the desired shape of aluminum veneer. This step requires the use of advanced processing equipment such as CNC machines to ensure machining accuracy and quality.

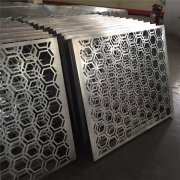

3. Surface treatment: The surface treatment of baked aluminum veneer is a crucial step. Aluminum veneer needs to be anodized to increase its surface hardness and wear resistance. Further spray paint treatment to increase its weather resistance and decorative properties. This step requires the use of equipment such as high-temperature ovens and high-pressure spray guns to ensure uniform coating and quality.

4. Film installation: During the production process of baked aluminum veneer, strict quality inspection and control are required. This includes inspection of raw materials, inspection of processing technology, quality testing of surface treatment, and acceptance of final products. Only through strict quality testing and control can the quality and performance of baked aluminum veneer meet the standard requirements.

2、 Quality control

1. Raw material inspection: During the production process, strict inspection and screening of raw materials are required to ensure product quality. This includes inspecting and testing the chemical composition, appearance dimensions, thickness, and other aspects of aluminum alloy sheets.

2. Process inspection: During the processing, it is necessary to inspect and monitor the accuracy of the processing equipment, the skill level of the operators, and other aspects to ensure the quality of the processing.

3. Surface treatment quality inspection: During the surface treatment process, it is necessary to inspect and test the uniformity, thickness, adhesion, and other aspects of the coating to ensure the quality of the coating.

4. Final product acceptance: During the production process, strict quality inspection and control of the final product are required, including appearance inspection, size measurement, performance testing, etc., to ensure that the product quality meets the standard requirements.

The production process and quality control of engineering baked aluminum veneer are very important links. Only through strict production management and quality control can the quality and performance of the product meet the standard requirements. In the future development, with the continuous advancement of technology and the increasing demand for building material performance, it is believed that painted aluminum veneer will play a more important role.

Customer service QQ

Customer service QQ