Industry information

Company News

- Imitation stone patterned aluminum veneer: the unique charm of modern architecture

- The unique charm of stone patterned aluminum veneer reveals the new trend of home decor

- Imitation stone patterned aluminum veneer: the "natural" choice for modern architecture

- Aluminum veneer customization, creating a new trend of personalized space

- Imitation stone patterned aluminum veneer: the beauty of nature, the choice of modernity

Industry dynamics

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum veneer customization, creating exclusive space aesthetics

- Stone patterned aluminum veneer: the new darling of architectural aesthetics

- Aluminum veneer: the fashionable new favorite of modern architecture

- Aluminum plate turning into wood grain, the beauty of the fusion of art and technology

Frequently asked questions

- What is the discoloration performance of aluminum veneer?

- What is the anti mold performance of aluminum veneer?

- What impact does the weight of aluminum veneer have on building structures?

- Can aluminum veneer be applied to different styles of architectural exterior design?

- What are the color and style options for aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786@qq.com

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

5 Requirements for Aluminum Veneer Packaging and Transportation

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: 2022-03-09 23:59:05

- Click:0

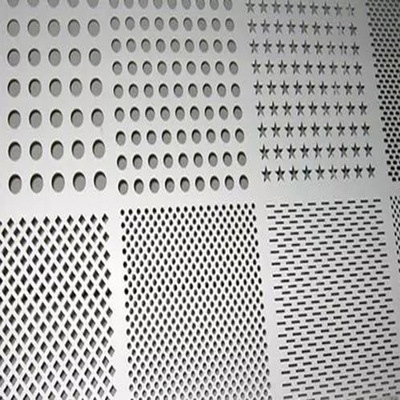

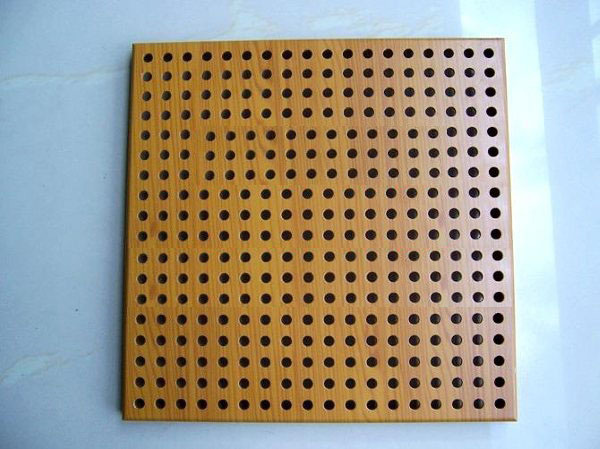

Aluminum veneerAs a commonly used building material, its packaging and transportation are also important links in ensuring product quality and customer satisfaction. Below, we will introduce 5 requirements for packaging and transportation of aluminum veneer.

1. Moisture resistance, sun protection, and shock resistance: Aluminum veneer is a material that is prone to moisture, sunburn, and vibration, so attention should be paid to moisture resistance, sun protection, and shock resistance during packaging and transportation. The aluminum veneer is usually packed with damp proof paper, foam pad and other materials to prevent it from being affected by moisture. Measures also need to be taken to prevent aluminum veneer from being affected by direct sunlight and vibration during transportation.

2. Avoid squeezing and friction: Aluminum veneers need to avoid being affected by squeezing and friction during packaging and transportation to prevent deformation or damage to the aluminum veneers. Usually, wooden boxes or pallets are used for packaging, and support structures are set inside the box to avoid the impact of compression on the aluminum veneer. During transportation, it is also necessary to avoid friction between aluminum veneer and other items to prevent surface scratches or damage.

3. Pollution prevention: Aluminum veneer needs to be protected from pollution during packaging and transportation to avoid affecting the quality and appearance of the product. Aluminum veneers are usually packaged in sealed bags or plastic films, and labeled with signs such as "fragile" and "moisture-proof" to remind transportation personnel to pay attention to protection.

4. Clear identification: Aluminum veneer needs to be clearly labeled during packaging and transportation for easy identification and handling. Usually, the product name, specifications, quantity, production date, and other information are labeled on the packaging, and a label is affixed outside the packaging to indicate the recipient's information and contact information, so that transportation personnel can contact the recipient in a timely manner.

5. Safety and reliability: Aluminum veneer needs to be ensured to be safe and reliable during packaging and transportation to avoid accidents. Usually, professional logistics companies are used for transportation, and relevant transportation contracts and insurance agreements are signed to ensure the safety and reliability of the goods. It is also necessary to comply with relevant laws, regulations, and industry standards to ensure the legality and compliance of the packaging and transportation process.

The packaging and transportation of aluminum veneer is one of the important links to ensure product quality and customer satisfaction. By adhering to requirements such as moisture resistance, sun protection, shock resistance, avoiding compression and friction, pollution prevention, clear labeling, and safety and reliability, enterprises can improve their quality management level and market competitiveness, and provide customers with higher quality products and services.

Customer service QQ

Customer service QQ