Industry information

Company News

- Imitation wood grain aluminum veneer: a green choice for modern architecture

- Aluminum veneer: the 'invisible hero' of modern architecture

- Aluminum veneer: Creating high-quality architectural appearance

- The unique charm of imitation wood grain aluminum veneer makes your home look brand new!

- Aluminum veneer: Creating the beauty of modern architecture, the new favorite material!

Industry dynamics

- Aluminum veneer: the 'invisible hero' of modern architecture

- High quality aluminum veneer shaped ceiling material

- Aluminum veneer: hidden home art master

- Aluminum veneer customization makes buildings more in line with people's aesthetic trends

- Aluminum veneer: not only a building material, but also a new favorite of architectural art

Frequently asked questions

- What impact does the weight of aluminum veneer have on building structures?

- Is the fire resistance of aluminum veneer related to its material?

- Will the use of aluminum veneer affect the waterproof performance of buildings?

- Can the insulation function of aluminum veneer reduce the amount of cement used in buildings?

- What are the color and style options for aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786@qq.com

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

What is the processing technology for aluminum veneer?

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: March 18, 2025 21:02:39

- Click:0

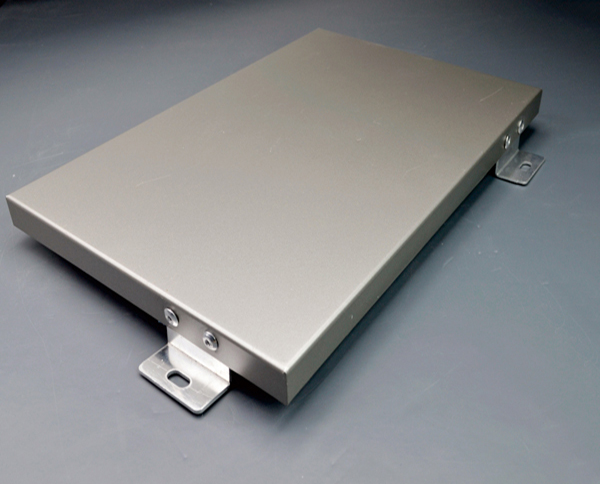

Aluminum veneerIt is a building material widely used in the fields of architecture, billboards, curtain walls, etc. Its processing technology is one of the important factors to ensure its quality and performance. The following will provide a detailed introduction to the processing technology and steps of aluminum veneer.

1. Raw material preparation

Before processing aluminum veneer, it is necessary to prepare the required raw materials, including aluminum plates, molds, cutting tools, etc. The quality of aluminum plates has a crucial impact on the quality of the final product, so it is necessary to choose high-quality aluminum plates as raw materials.

1. Cutting and processing

The cutting and processing of aluminum veneer is the most basic step in its processing, mainly carried out through CNC machine tools or manual tools. Numerical control machine tools can achieve high-precision and high-efficiency cutting and processing, while manual tools require experienced workers to operate. During the cutting process, attention should be paid to avoiding scratches and burrs to ensure the flatness and smoothness of the aluminum veneer surface.

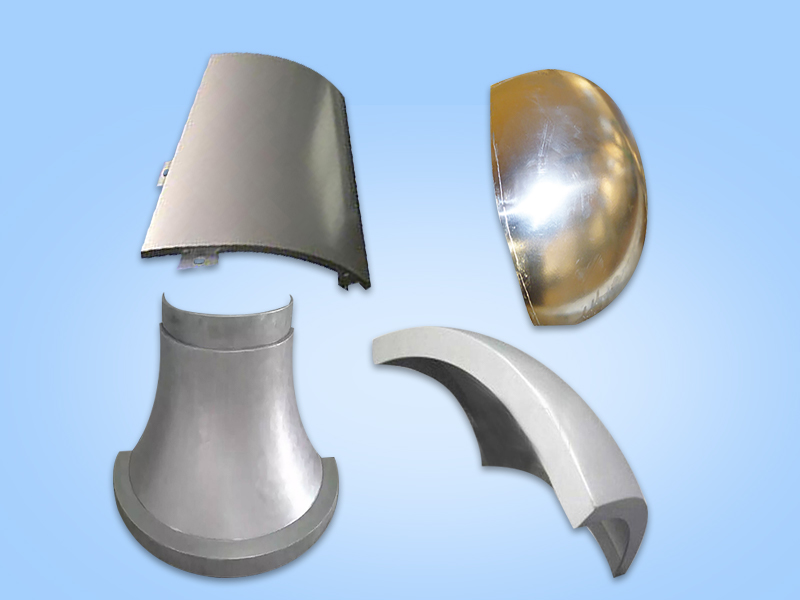

1. Bending processing

The bending process of aluminum veneer is a relatively complex step in its manufacturing process, mainly carried out through bending machines. During the bending process, it is necessary to pay attention to maintaining the uniform thickness of the aluminum plate to avoid problems such as deformation and cracks. At the same time, it is necessary to determine the bending angle and position of the aluminum veneer according to the design requirements to ensure that it meets the usage requirements.

1. Drilling processing

The punching process of aluminum veneer is a common step in its manufacturing process, mainly carried out through drilling or punching machines. During the drilling process, attention should be paid to maintaining the accuracy and consistency of the aperture to avoid deviations and errors. At the same time, it is necessary to determine the position and quantity of the holes according to the design requirements to ensure that they meet the usage requirements.

1. Welding processing

The welding process of aluminum veneer is an important step in its manufacturing process, mainly carried out through welding machines. During the welding process, it is necessary to pay attention to controlling the welding temperature and welding time to avoid problems such as wide or narrow welds. At the same time, it is necessary to determine the welding position and method according to the design requirements to ensure that it meets the usage requirements.

The processing technology of aluminum veneer is a complex and rigorous process that requires multiple steps to be completed. Consumers should choose aluminum veneer according to their actual usage needs to ensure that its performance meets the requirements. Attention should also be paid to the characteristics of materials and structural limitations during design and installation to ensure that the construction effect meets the requirements.

Customer service QQ

Customer service QQ