Industry information

Company News

- Stone patterned aluminum veneer: natural art in modern architecture

- Imitation wood grain aluminum veneer: an art of collision between modern and traditional

- Stone patterned aluminum veneer: the new favorite of fashion and practicality in architecture

- 2. "New Fashion of Aluminum Veneer: Imitation of Stone Patterns, Extremely Beautiful!" 3 Explore

- Imitation stone patterned aluminum veneer: the new aesthetic favorite of modern architecture

Industry dynamics

- Imitation wood grain aluminum veneer, the green new favorite of modern architecture

- What is the wind pressure resistance performance of aluminum veneer?

- Aluminum veneer customization, creating a new trend of personalized space

- 5 Requirements for Aluminum Veneer Packaging and Transportation

- UV resistance and wear resistance of curtain wall aluminum veneer

Frequently asked questions

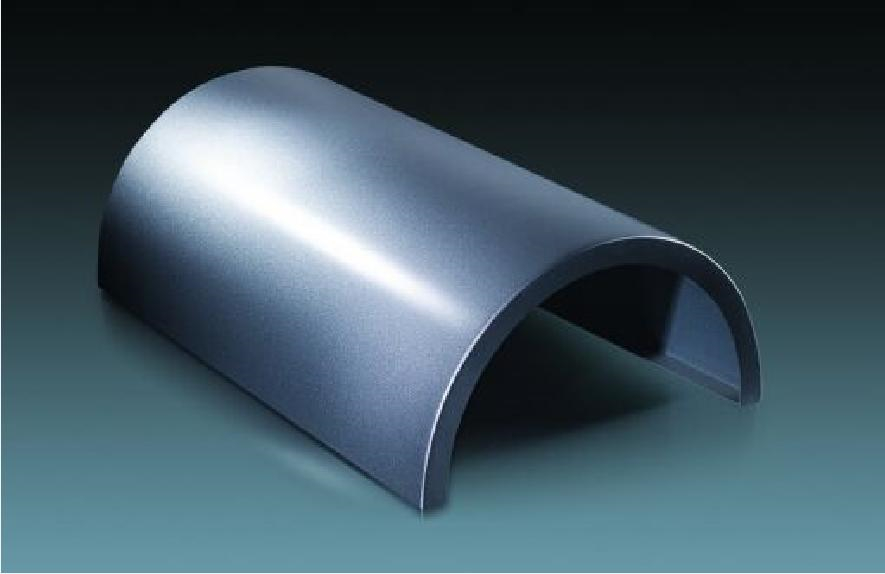

- Can aluminum veneer be used for architectural arch design?

- What impact does the weight of aluminum veneer have on building structures?

- Will the use of aluminum veneer affect the waterproof performance of buildings?

- What is the anti mold performance of aluminum veneer?

- Can aluminum veneer be applied to different styles of architectural exterior design?

contact us

Mobile:+86 15627778610

Email: 2201229786@qq.com

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Detailed explanation of anti-corrosion treatment methods for aluminum veneer

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: February 26, 2025 15:04:58

- Click:0

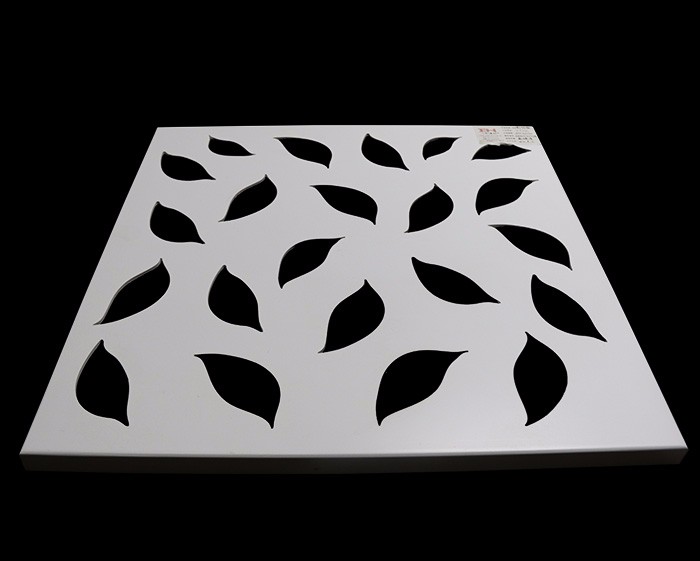

Aluminum veneerAs a new type of building material, it has the advantages of lightweight, corrosion resistance, and easy processing, and has been widely used in the field of architectural decoration. Aluminum veneer is susceptible to corrosion during use, which can affect its service life and appearance. It is very necessary to carry out anti-corrosion treatment on aluminum veneer. Below, we will provide a detailed introduction to the anti-corrosion treatment methods for aluminum veneer.

1、 Surface treatment method

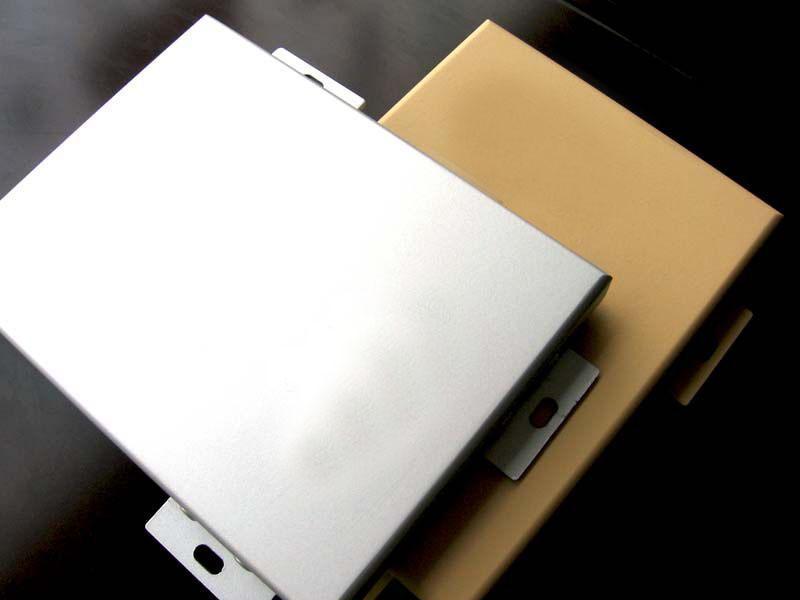

1. Anodizing: By electrolytic oxidation, the surface of aluminum veneer is transformed into an aluminum oxide film layer, thereby improving its surface hardness and wear resistance. The aluminum oxide film layer also has a certain anti-corrosion effect, which can effectively protect the surface of aluminum veneer from corrosion.

2. Fluorocarbon spraying: By spraying fluorocarbon coating, a layer of fluorocarbon film is formed on the surface of aluminum veneer to improve its weather resistance and corrosion resistance. Fluorocarbon coatings have good weather resistance and UV resistance, and can maintain stable color and appearance effects in outdoor environments for a long time.

2、 Chemical treatment methods

1. Phosphate treatment: By applying phosphate solution on the surface of aluminum veneer, a phosphate film layer can be formed to improve its corrosion resistance and wear resistance. The phosphate film layer can also prevent rust and dirt from forming on the surface of aluminum veneer, maintaining its appearance and cleanliness.

2. Ammonium sulfate treatment: By applying ammonium sulfate solution on the surface of aluminum veneer, a layer of ammonium sulfate film can be formed, thereby improving its corrosion resistance and wear resistance. The ammonium sulfate film layer can also promote passivation reactions on the surface of aluminum veneer, enhancing its corrosion resistance.

3、 Electrochemical treatment method

1. Electrolytic polishing: By electrolytic polishing, the oxide layer and dirt are removed from the surface of aluminum veneer, forming a shiny metal surface. This processing method can improve the surface glossiness and aesthetics of aluminum veneer, while also enhancing its corrosion resistance.

2. Electrolytic coloring: By electrolytic coloring, a layer of pigment or dye is coated on the surface of aluminum veneer to present different colors and appearance effects. This processing method can not only beautify the appearance of aluminum veneer, but also improve its corrosion resistance.

4、 Conclusion and Prospect

By anti-corrosion treatment of aluminum veneer, its service life and appearance can be effectively extended, and maintenance costs can be reduced. In the future, with the continuous advancement of technology and the increasing awareness of environmental protection among people, the anti-corrosion treatment technology of aluminum veneer will be better developed and applied. It is also necessary to strengthen relevant research and experiments to further improve the quality and performance of aluminum veneer to meet different market demands.

Customer service QQ

Customer service QQ