Industry information

Company News

- Aluminum veneer customization, creating a new trend of personalized space

- Fashion interpretation of imitation wood grain aluminum veneer: perfect integration of nature and architecture

- Stone patterned aluminum veneer, the beauty of nature lies within one board

- Stone patterned aluminum veneer: the fashionable choice for modern architecture?

- Stone patterned aluminum veneer: a delicate interpretation of architectural art

Industry dynamics

- Stone patterned aluminum veneer, creating a new fashion for home decor

- Advantages of aluminum veneer in high-rise buildings

- Aluminum veneer: understated elegance in modern architecture

- Aluminum veneer makes buildings more environmentally friendly and sustainable

- Aluminum veneer: a fashionable choice in modern architecture

Frequently asked questions

- Will the use of aluminum veneer affect the waterproof performance of buildings?

- Can aluminum veneer be applied to different styles of architectural exterior design?

- What is the discoloration performance of aluminum veneer?

- What impact does the weight of aluminum veneer have on building structures?

- What are the color and style options for aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786@qq.com

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

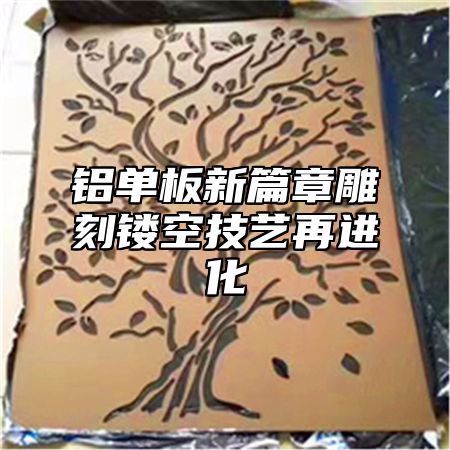

New chapter in aluminum veneer carving and hollowing techniques: further evolution

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: March 3, 2025 13:54:15

- Click:0

Aluminum veneerAs a new type of building material, it has excellent decorative effects and durability. During the production process, carving and hollowing out are important techniques for aluminum veneer, which can bring more exquisite effects to architectural decoration. With the continuous advancement of technology and the continuous development of society, the carving and hollowing techniques of aluminum veneer are also constantly evolving and innovating, bringing us more exquisite and unique architectural decoration effects.

1、 Design phase

1. Determine design plan: The designer develops a corresponding design plan based on the client's needs and the style of the building. The design plan includes requirements for patterns, colors, textures, and other aspects. Designers need to fully consider these factors to ensure that the final decorative effect meets the customer's requirements.

2. Sketching: The designer converts the design proposal into a sketch and communicates and confirms it with the client. Sketches are an important basis for making aluminum veneers and must be accurate and error free.

2、 Production stage

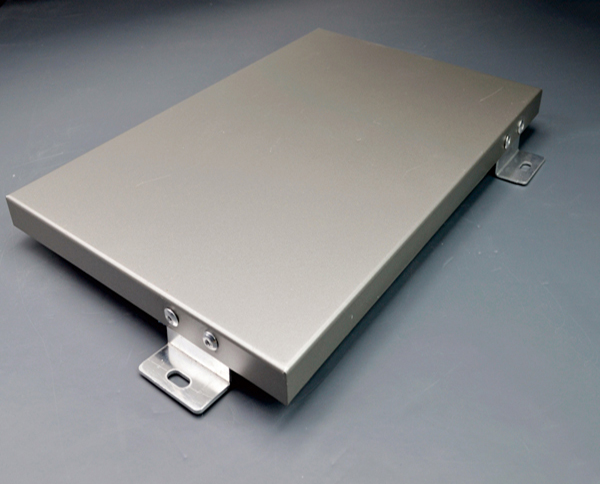

1. Raw material preparation: The main raw materials for aluminum veneer are aluminum plates and spray coatings. Aluminum plates need to undergo precision cutting and polishing processes to ensure a smooth and even surface. Spray coating requires selecting the appropriate color and texture according to the design plan.

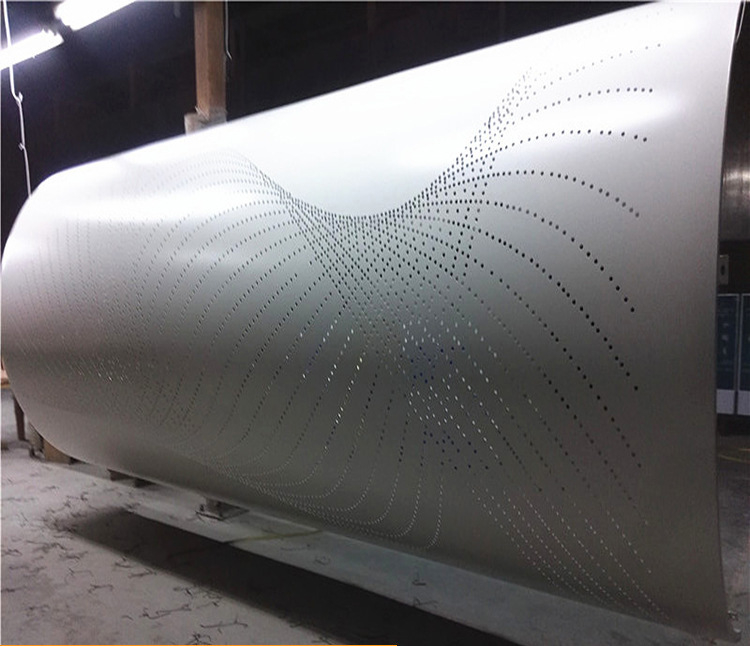

2. Carving treatment: Carving treatment is one of the key technologies in the production of aluminum veneer. Through high-precision carving equipment and technology, precise carving of various materials can be achieved, resulting in more exquisite patterns and textures.

3. Hollow out treatment: Hollow out treatment is a further extension of carving treatment, which can remove some areas in the aluminum veneer through carving technology to form a unique hollow out effect. Hollow out treatment needs to consider the stability and safety of the structure, and should be operated by experienced craftsmen.

4. Spray treatment: Spray treatment is one of the key steps in the production of aluminum veneer. Spray paint needs to be evenly sprayed onto the aluminum plate to form the desired pattern and texture. During the spraying process, attention should be paid to controlling the thickness and uniformity of the coating to ensure that the final decorative effect meets the design requirements.

3、 Installation phase

1. On site measurement: Before installation, it is necessary to conduct on-site measurements of the building to determine the size and position of the aluminum veneer. The measurement results need to be compared with the design drawings to ensure installation accuracy and quality.

2. Installation and fixation: Aluminum veneer needs to be fixed to the building by welding or bolts. Pre treatment of the aluminum plate is required before fixation to ensure the firmness and safety of welding or bolts.

With the continuous advancement of technology and the continuous development of society, the carving and hollowing techniques of aluminum veneer are also constantly evolving and innovating. Through continuous exploration and experimentation, we can create more exquisite and unique architectural decorative effects. In the future, aluminum veneer will play a more important role in creating a better and more comfortable living environment for people.

Customer service QQ

Customer service QQ