Industry information

Company News

- Stone patterned aluminum veneer: the new aesthetic favorite of modern architecture

- Imitation Wood Grain Aluminum Veneer: Natural Charm in Modern Architecture

- Aluminum veneer customization: an artistic journey to create personalized spaces

- Stone patterned aluminum veneer: a perfect combination of fashion and practicality

- Aluminum veneer: understated luxury in architecture

Industry dynamics

- Twisted painted aluminum veneer creates a new choice for modern architectural appearance

- Exploring the environmental advantages of aluminum veneer curtain walls

- How to evaluate the cost-effectiveness of aluminum veneer in modern architecture?

- The advantages of aluminum veneer are durability, aesthetics, and environmental friendliness

- 2. "New trend of aluminum veneer: imitation stone pattern, perfect combination of fashion and practicality" 3 "...

Frequently asked questions

- What are the color and style options for aluminum veneer?

- What is the discoloration performance of aluminum veneer?

- Can aluminum veneer be used for architectural arch design?

- What is the strength of aluminum veneer?

- Is the fire resistance of aluminum veneer related to its material?

contact us

Mobile:+86 15627778610

Email: 2201229786@qq.com

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

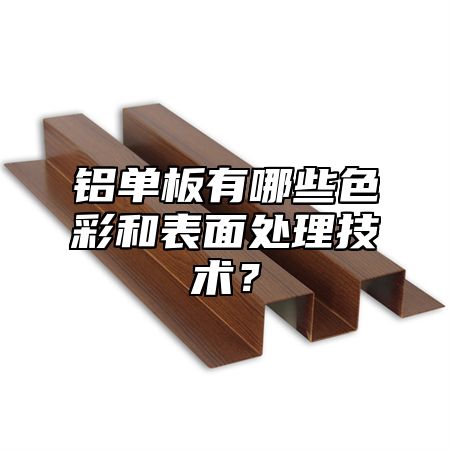

What are the colors and surface treatment techniques for aluminum veneer?

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: 2022-03-07 12:35:51

- Click:0

Aluminum veneerAs a commonly used building material, its surface treatment technology and color are rich and diverse. Let's take a detailed look at the color and surface treatment techniques of aluminum veneer:

1. Color

The color of aluminum veneer can be customized according to different usage needs. Common colors include white, gray, black, gold, silver, etc. We can also dye or paint according to customer requirements to meet personalized needs.

1. Surface treatment technology

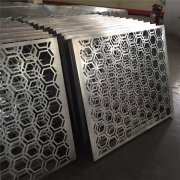

The surface treatment techniques for aluminum veneer mainly include anodizing, spraying, and rolling. Anodizing is the most common surface treatment technique with the following advantages:

Good corrosion resistance: After anodizing treatment, a dense oxide film is formed on the surface of the aluminum veneer, which can resist the erosion of harsh environments such as acid rain and salt spray, thereby extending the service life of the aluminum veneer.

High aesthetic appeal: The surface of aluminum veneer after anodizing treatment presents a metallic luster and has a good decorative effect.

Strong wear resistance: After anodizing treatment, the surface hardness of aluminum veneer increases, and the wear resistance is also improved.

In addition to anodizing, spraying and rolling are also common surface treatment techniques. Spraying can present various colors and patterns on the surface of aluminum veneer, while also improving its corrosion resistance and decorative effect. Rolling can make the surface of aluminum veneer present a smoother texture, and it can also be dyed in various colors.

Aluminum veneer comes in a variety of colors and can be customized according to different usage needs; And its surface treatment techniques mainly include anodizing, spraying, roller pressing, etc., each of which has its unique advantages and applicable scope. When selecting aluminum veneer, it is necessary to choose the appropriate surface treatment technology and color according to actual needs to ensure the overall aesthetics and service life of the building.

Customer service QQ

Customer service QQ