Industry information

Company News

- Aluminum veneer customization, creating a new trend of personalized space

- Imitation stone patterned aluminum veneer: the fashionable "stone" charm of modern architecture

- Fashion interpretation of imitation wood grain aluminum veneer: perfect integration of nature and architecture

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum veneer: understated luxury in modern architecture

Industry dynamics

- 2. Wood grain aluminum veneer adds a natural touch to architecture The new trend of aluminum plate

- Innovative application of aluminum veneer in landscape design

- Aluminum veneer customization, creating a new trend of personalized space

- Green and environmentally friendly subway station aluminum ceiling creates a healthy travel space

- Is the construction period of aluminum veneer long?

Frequently asked questions

- What is the anti mold performance of aluminum veneer?

- Can the insulation function of aluminum veneer reduce the amount of cement used in buildings?

- Will the use of aluminum veneer affect the waterproof performance of buildings?

- Can aluminum veneer be applied to different styles of architectural exterior design?

- Can aluminum veneer be used for architectural arch design?

contact us

Mobile:+86 15627778610

Email: 2201229786@qq.com

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

So how is this curved aluminum veneer processed and formed?

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: 2022-03-18 22:21:44

- Click:0

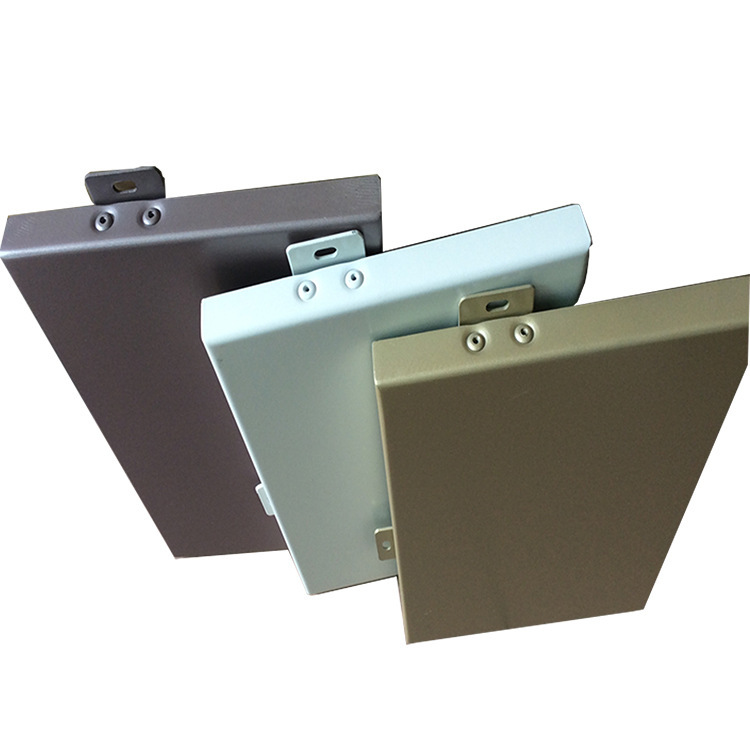

Arc-shapedAluminum veneerIt is a common building decoration material, and its unique curved appearance and excellent performance characteristics have made it widely used in modern architecture. Next, we will provide a detailed introduction to the processing and forming process of curved aluminum veneer.

1. Design drawings

Firstly, it is necessary to create design drawings based on the customer's requirements, including determining parameters such as curvature, length, and width. The design drawings need to be precise and clear for subsequent production and processing.

1. Raw material preparation

The main raw material for curved aluminum veneer is aluminum alloy sheet, and different specifications and qualities of materials need to be selected according to the requirements of the design drawings. Other auxiliary materials such as angle irons and fasteners need to be prepared.

1. Cutting and processing

Cut and process the raw materials according to the requirements of the design drawings to obtain the desired size and shape. Cutting and processing can be carried out using CNC machine tools or manual operations, requiring high precision and accurate dimensions.

1. Bending processing

Bend the cut aluminum plate to achieve the desired curvature and shape. Bending processing can be carried out using CNC bending machines or manual operations, requiring high precision and good stability.

1. Welding processing

Weld the bent aluminum plate to form the desired structure and connection method. Welding processing can be carried out using argon arc welding machine or manual arc welding, requiring firm welding, no porosity, no slag inclusion or other defects.

1. Surface treatment

Surface treatment of welded curved aluminum veneer, such as anodizing, spraying, drawing, etc., to improve its corrosion resistance and decorative properties. Surface treatment requires selecting appropriate processes and materials, and strictly following the process flow for operation.

The processing and forming process of curved aluminum veneer includes multiple steps such as design drawings, raw material preparation, cutting, bending, welding, and surface treatment. These processes require strict quality and precision control to ensure that the final product meets customer needs and standard requirements.

Customer service QQ

Customer service QQ