Industry information

Company News

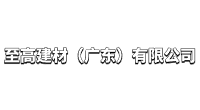

- Aluminum veneer customization, creating a new proposition for personalized space!

- Imitation stone patterned aluminum veneer: the finishing touch of modern architecture?

- Stone patterned aluminum veneer: the beauty of nature, in architecture

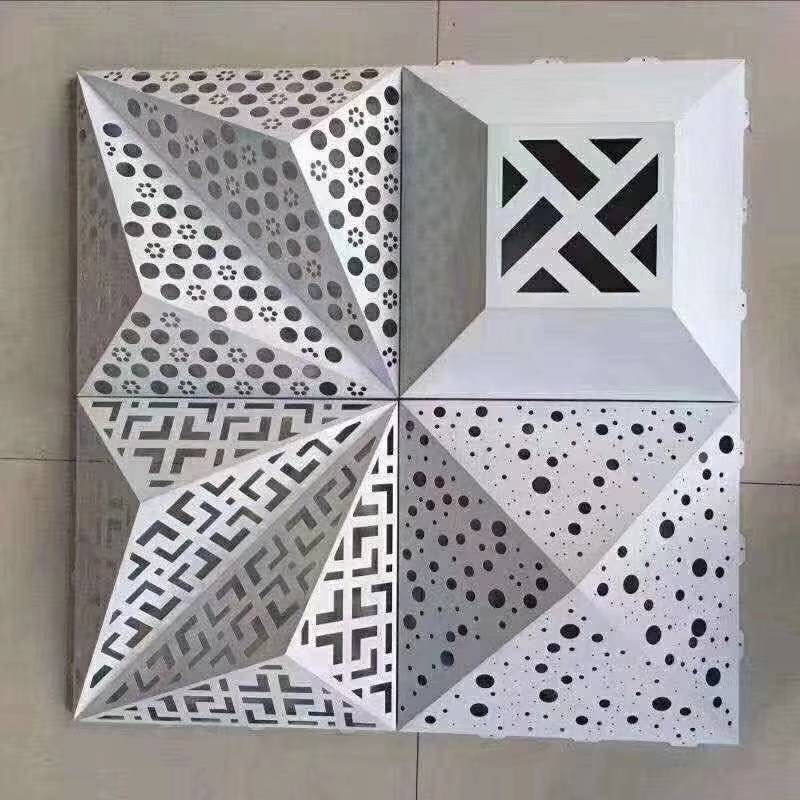

- Aluminum veneer: the "lightweight" and fashionable choice for modern architecture

- Imitation wood grain aluminum veneer: a green choice for modern architecture

Industry dynamics

- Process characteristics and advantages of carved curved aluminum veneer

- What are the types of surface coatings for curtain wall aluminum panels?

- Research on the future development direction of aluminum veneer manufacturers

- The unique charm of wood grain aluminum veneer creates a new trend in home decor

- Imitation stone patterned aluminum veneer, creating a new style of modern architecture

Frequently asked questions

- What is the discoloration performance of aluminum veneer?

- Can the insulation function of aluminum veneer reduce the amount of cement used in buildings?

- Can aluminum veneer be used for architectural arch design?

- Is the fire resistance of aluminum veneer related to its material?

- Will the use of aluminum veneer affect the waterproof performance of buildings?

contact us

Mobile:+86 15627778610

Email: 2201229786@qq.com

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Exploration of Processing Technology and Techniques for 3mm Arc Aluminum Veneer

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: March 3, 2025 06:48:10

- Click:0

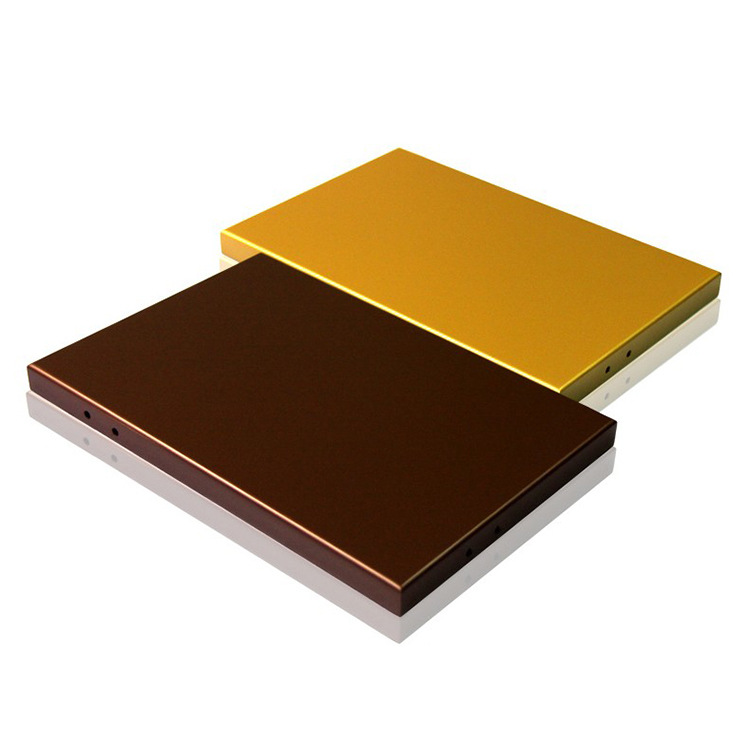

circular arcAluminum veneerIt is a new type of building material with many advantages and characteristics. The selection of processing technology and techniques has a crucial impact on the quality and effectiveness of the product. Today we will discuss the processing technology and techniques for 3mm curved aluminum veneer.

1、 Processing technology

1. Cutting: Firstly, the aluminum alloy sheet needs to be cut into the required size and shape.

2. Bending: Bend the cut aluminum alloy sheet to form the desired circular arc shape.

3. Polishing: Polish the bent aluminum alloy sheet to make its surface smoother and more aesthetically pleasing.

4. Welding: Weld the polished aluminum alloy sheet to form a complete curved aluminum veneer.

2、 Technology selection

1. CNC machining technology: CNC machining technology can achieve high-precision machining, improve product accuracy and quality.

2. Laser cutting technology: Laser cutting technology can achieve fast and efficient cutting, improving production efficiency.

3. Automated production line: Automated production lines can achieve a fully automated production process, improving production efficiency and product quality.

3、 Processing advantages

1. High precision: The use of CNC machining technology and laser cutting technology can achieve high-precision machining, ensuring product quality and accuracy.

2. High production efficiency: The use of automated production lines can achieve a fully automated production process, improving production efficiency and product quality.

3. Environmental protection and energy conservation: No harmful substances are produced during the processing, which meets the requirements of modern society for environmental protection.

4、 Application prospects

With the development of the construction industry, curved aluminum veneer will be more widely used and developed. It will become an indispensable part of architectural decoration, bringing a better experience and feeling to people's lives and work. We will continue to adhere to the business philosophy of "quality first, customer first", continuously improve our technology and service level, and provide customers with higher quality products and services.

Customer service QQ

Customer service QQ