Industry information

Company News

- Aluminum veneer: the fashionable choice of modern architecture, revealing its charm!

- Stone patterned aluminum veneer: the natural charm of modern architecture

- Aluminum veneer: understated luxury in modern architecture

- Aluminum veneer: the elegant choice in modern architecture

- Aluminum veneer customization, creating a new trend of personalized space

Industry dynamics

- The secret of aluminum veneer: a leap from architecture to art

- Imitation wood grain aluminum veneer, the new favorite of green fashion in modern architecture

- Aluminum veneer: the fashionable "coat" in modern architecture

- What impact does the surface treatment method of aluminum veneer have on its price?

- Aluminum veneer customization, creating a new trend of personalized space

Frequently asked questions

- What impact does the weight of aluminum veneer have on building structures?

- What is the strength of aluminum veneer?

- What is the discoloration performance of aluminum veneer?

- Will the use of aluminum veneer affect the waterproof performance of buildings?

- Can the insulation function of aluminum veneer reduce the amount of cement used in buildings?

contact us

Mobile:+86 15627778610

Email: 2201229786@qq.com

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Research on Surface Treatment and Corrosion Resistance of 3mm Carved Aluminum Veneer

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: March 18, 2025 03:49:57

- Click:0

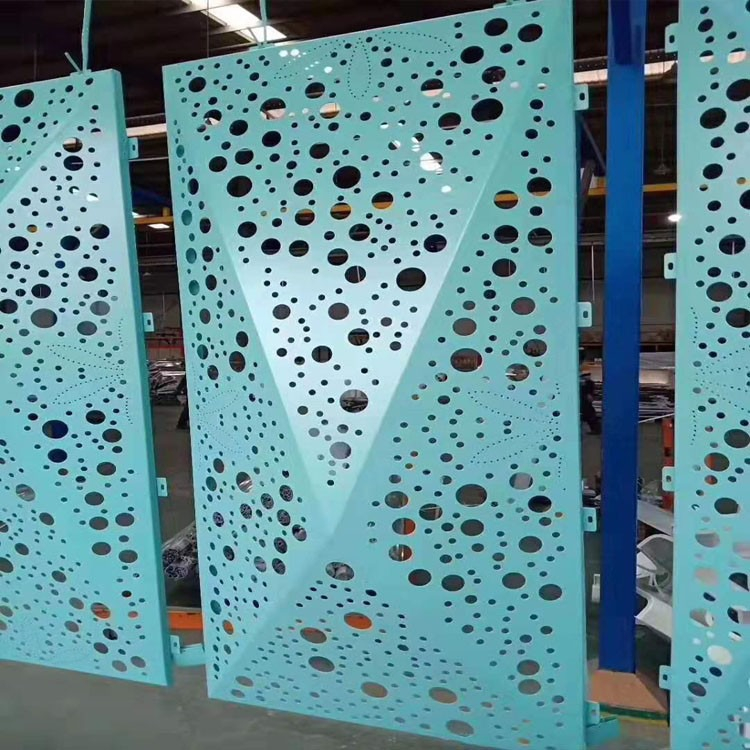

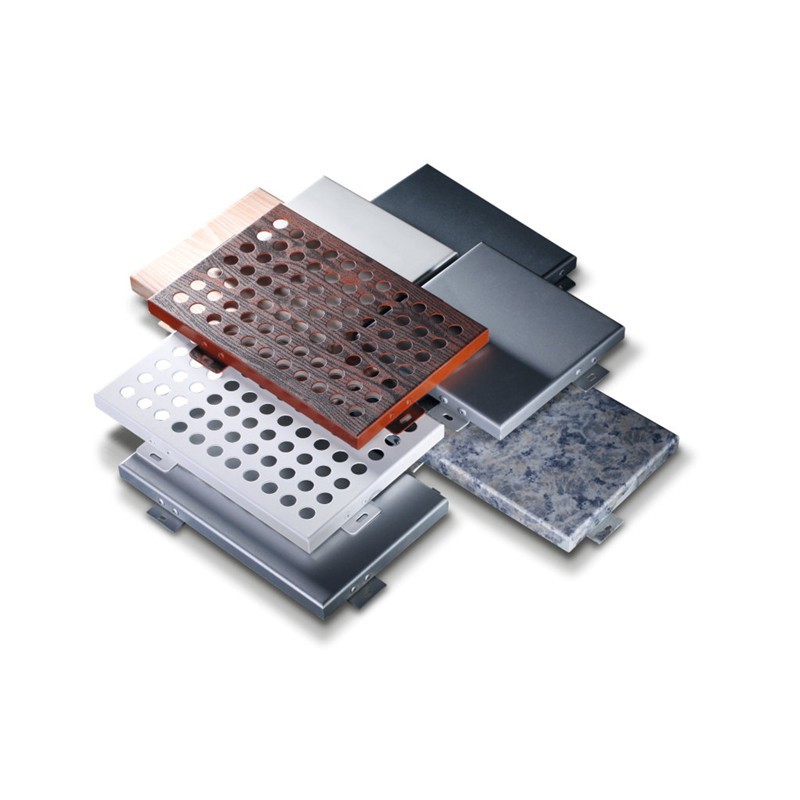

3mm carvingAluminum veneerIt is a high-end decorative material, and its surface treatment and anti-corrosion performance have a crucial impact on its decorative effect and service life. Below is a detailed introduction to the surface treatment and anti-corrosion performance of 3mm carved aluminum veneer.

1、 Surface treatment

1. Anodizing treatment

Anodizing treatment is one of the commonly used surface treatment techniques for 3mm carved aluminum veneer. The processing includes steps such as electrolysis, cleaning, and staining. After anodizing treatment, 3mm carved aluminum veneer can achieve very strong corrosion resistance and aesthetics.

2. Spray treatment

Spray coating treatment is another commonly used surface treatment technique that can provide richer colors and glossiness for 3mm carved aluminum veneer. The processing includes steps such as primer and topcoat, which need to be selected and applied according to different design requirements.

3. Matte treatment

Matte treatment is a special surface treatment technique that can provide a more delicate texture and touch for 3mm carved aluminum veneers. This processing can be achieved through mechanical or chemical methods, and needs to be selected and applied according to specific design requirements.

2、 Research on anti-corrosion performance

1. Electrochemical testing

Electrochemical testing is a commonly used method for testing corrosion resistance, which can quantitatively evaluate the corrosion resistance of 3mm carved aluminum veneer. This testing method mainly includes polarization curve testing and potential current curve testing, which can evaluate the corrosion resistance of aluminum veneer in different environments.

2. Salt spray test

Salt spray test is a common anti-corrosion performance testing method that can simulate the erosion effect of marine environment on 3mm carved aluminum veneer. This testing method evaluates the corrosion degree and corrosion resistance of aluminum veneers at different time periods by placing them in a salt spray environment for testing.

3. Hydrostatic test

Hydrostatic testing is a rigorous method for evaluating the corrosion resistance of 3mm carved aluminum veneer in a water pressure environment. This testing method requires placing aluminum veneer in high-pressure water for testing to evaluate its corrosion resistance under different water pressures.

The surface treatment and anti-corrosion performance of 3mm carved aluminum veneer have a significant impact on its decorative effect and service life. By adopting different surface treatment techniques and anti-corrosion performance testing methods, the quality and performance of 3mm carved aluminum veneer can be effectively improved to meet the decoration needs of different occasions.

Customer service QQ

Customer service QQ