Industry information

Company News

- Aluminum veneer: the secret weapon of architectural aesthetics

- Stone patterned aluminum veneer adds a sense of "stone" to the space

- Aluminum veneer customization, creating your own space beauty

- Imitation wood grain aluminum veneer: the green new favorite of modern architecture

- Aluminum veneer: a low-key luxury choice in modern architecture

Industry dynamics

- The widespread use of hyperbolic hollow aluminum veneer in modern architecture

- What are the engineering examples of curtain wall aluminum veneer?

- Analysis of Waterproof Characteristics of Fluorocarbon Aluminum Veneer

- Aluminum veneer manufacturer's production line technology upgrade

- 2. New favorite of aluminum materials - Unveiling the charm of imitation wood grain aluminum veneer. 3 The 'wood' in the aluminum veneer industry

Frequently asked questions

- Can aluminum veneer be used for architectural arch design?

- Can the insulation function of aluminum veneer reduce the amount of cement used in buildings?

- What is the discoloration performance of aluminum veneer?

- Is the fire resistance of aluminum veneer related to its material?

- What are the color and style options for aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786@qq.com

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

What is the production process of aluminum veneer?

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: March 18, 2025 00:46:57

- Click:0

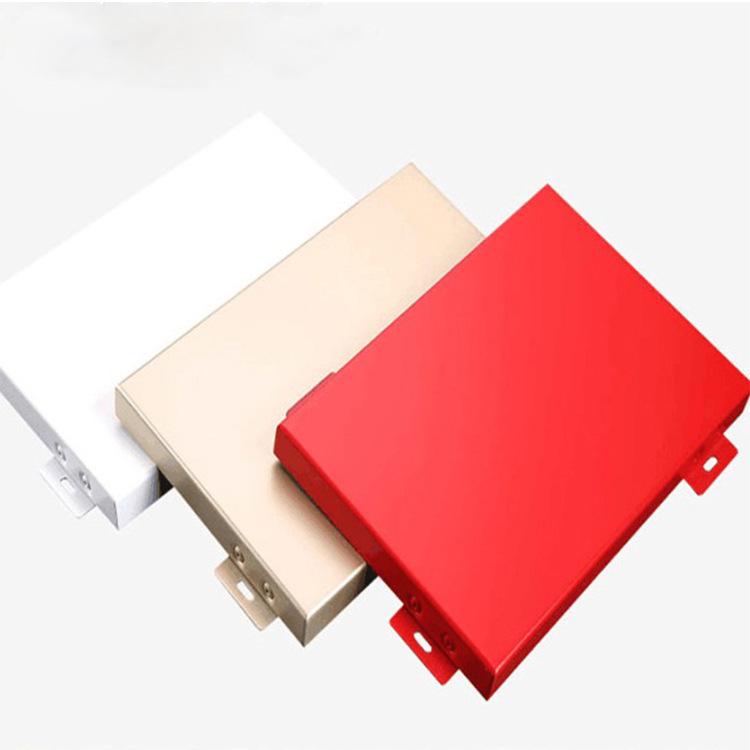

Aluminum veneerIt is a common building material, and its production process includes multiple stages. Below is a detailed introduction to the production process of aluminum veneer.

1. Raw material preparation

The main raw materials for aluminum veneer are aluminum and surface treatment materials. Before production, it is necessary to test and screen the raw materials to ensure that their quality meets the requirements. It is also necessary to select suitable aluminum materials and surface treatment materials according to the requirements of the design drawings to ensure the performance and appearance of the final product.

1. Cutting and processing

After preliminary treatment, aluminum materials need to be cut and processed. Cutting processing is the process of cutting aluminum into the required size, usually using modern equipment such as CNC machine tools for processing. The quality of cutting processing directly affects the smooth progress of subsequent processes.

1. Forming and processing

The cut aluminum material needs to be processed into the desired shape through molding. The commonly used forming processing methods include bending, bending, stamping, etc. The quality of forming processing directly affects the appearance and strength of aluminum veneer.

1. Surface treatment

The surface of aluminum veneer needs to be treated to improve its corrosion resistance and aesthetics. There are many ways of surface treatment, such as anodizing, spraying, electrophoretic coating, etc. Different surface treatment methods will have different effects on the performance and appearance of aluminum veneer.

1. Welding installation

Aluminum veneer requires welding treatment during installation, usually using methods such as argon arc welding or TIG welding. The quality of welding directly affects the strength and stability of aluminum veneer. Attention should also be paid to safety issues during the welding process to avoid accidents.

1. Check the packaging

Aluminum veneer needs to be inspected and packaged. Inspection is to ensure that the quality of the product meets the requirements, while packaging is to protect the product from damage and contamination. Usually, cardboard or wooden boxes are used for packaging, and measures such as moisture-proof and shockproof are added.

The production process of aluminum veneer is a complex process that requires precise operation and management in multiple stages. Only by strictly following relevant standards can high-quality aluminum veneer products be produced.

Customer service QQ

Customer service QQ